Preliminary mixing can be performed at low speed running, similar to manual mixing.

- * Low speed ⇒ medium speed ⇒ high speed running can also be performed by using step operation.

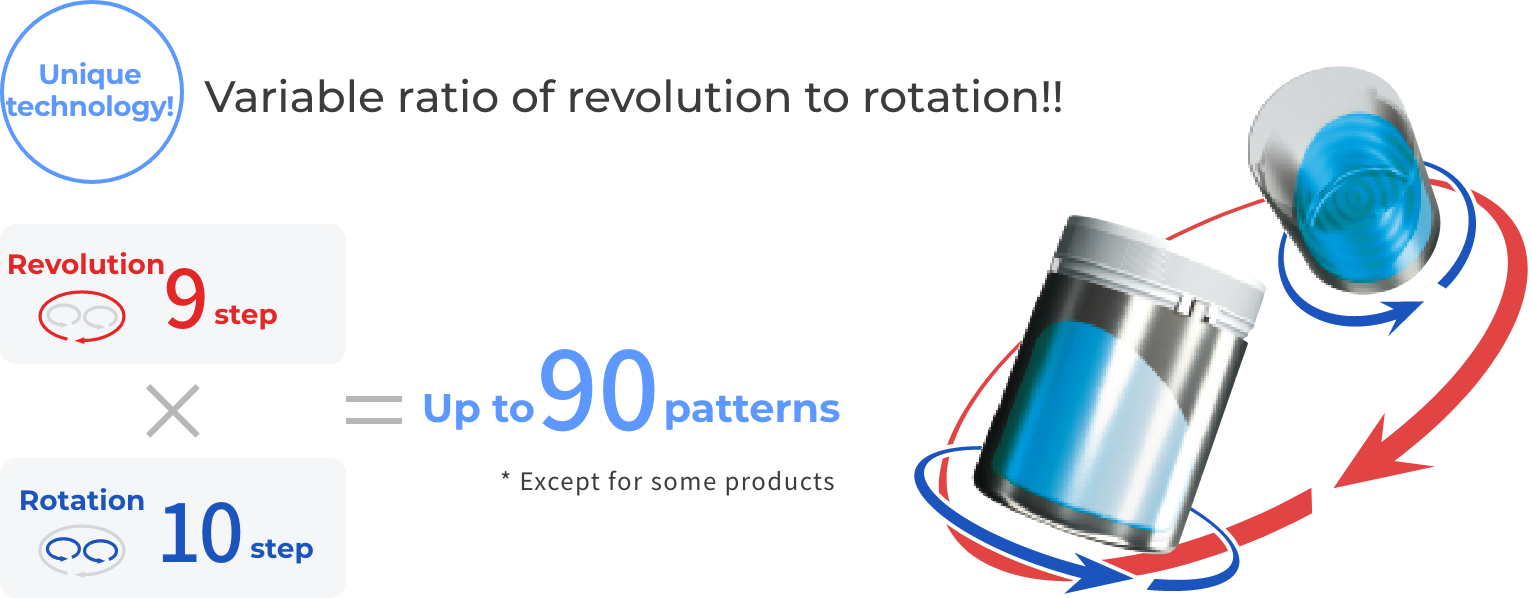

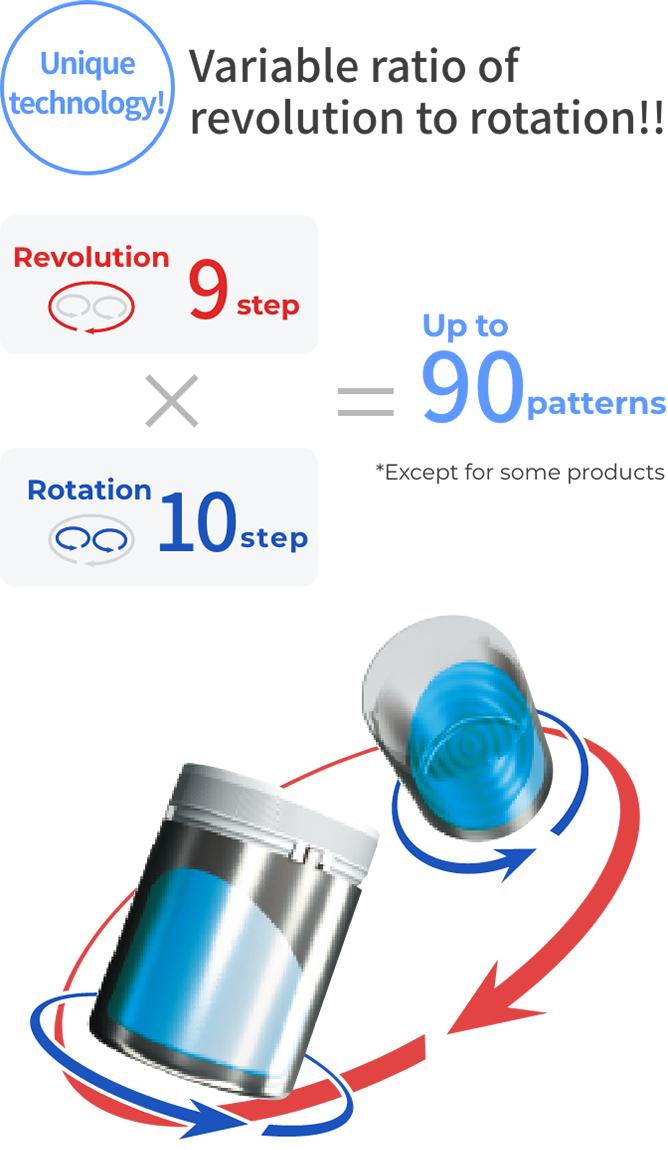

The speed of rotation and the speed of revolution are independent with “Kakuhunter”.

The ratio of revolution to rotation can be changed with up to 90 rotational patterns.

Insufficient Mixing and Defoaming

As the ratio of rotation is fixed,

mixing fails or lumps tend

to easily form even if the

speed of revolution is adjusted.

Temperatures Rises of Materials by Frictional Heat

The temperatures of materials

rise due to frictional heat of

mixing.

Precipitation of Materials with Insufficient Viscosity

With materials having different

specific gravities, viscosity

decreases and materials

higher in specific gravity

are precipitated.

Individual Revolution and Rotation

Speed Control System,

Resolving These Issues

Kakuhunter,allowing up to 9 steps of revolution and 10 steps of rotation,

can resolve the issues of the ratio of rotation fixed type.

For the materials being mixed, the optimum speeds of rotation and revolution vary depending on their amounts, viscosity, and other characteristics. Rotating more than required will increase stress on materials, such as temperature rise and damage, affecting its quality. Kakuhunter can change the ratio of revolution to rotation, allowing up to 9 steps of revolution and 10 steps of rotation with up to 90 patterns, so that the issues of the fixed rotation ratio type can be resolved.

Advantage01

Resolution of Insufficient Mixing

Insufficient mixing and lumps are suppressed by increasing the ratio of rotation.

Advantage02

Efficiency Enhancement / Uniform Dispersion

Materials high in powder ratio are dispersed efficiently and uniformly in a short time by optimizing the setting conditions.

Advantage03

Continuous Running by Function

Preliminary mixing can be performed at low speed running, similar to manual mixing.

Advantage04

Rotation Cutting Function

Materials can be separated intentionally by zero-setting the rotation.

(Example) Separation of aluminum solution

Advantage05

Powerful Mixing

Short-time processing is realized efficiently since the speed of rotation can be set at a ratio of up to 1:1 with respect to the speed of revolution.

Advantage06

Versatility + Optimization

Various materials are handled with versatility (in mixing, defoaming, dispersing, crushing, kneading, separating, and emulsifying).

(processed under optimum conditions appropriate for the purpose.)

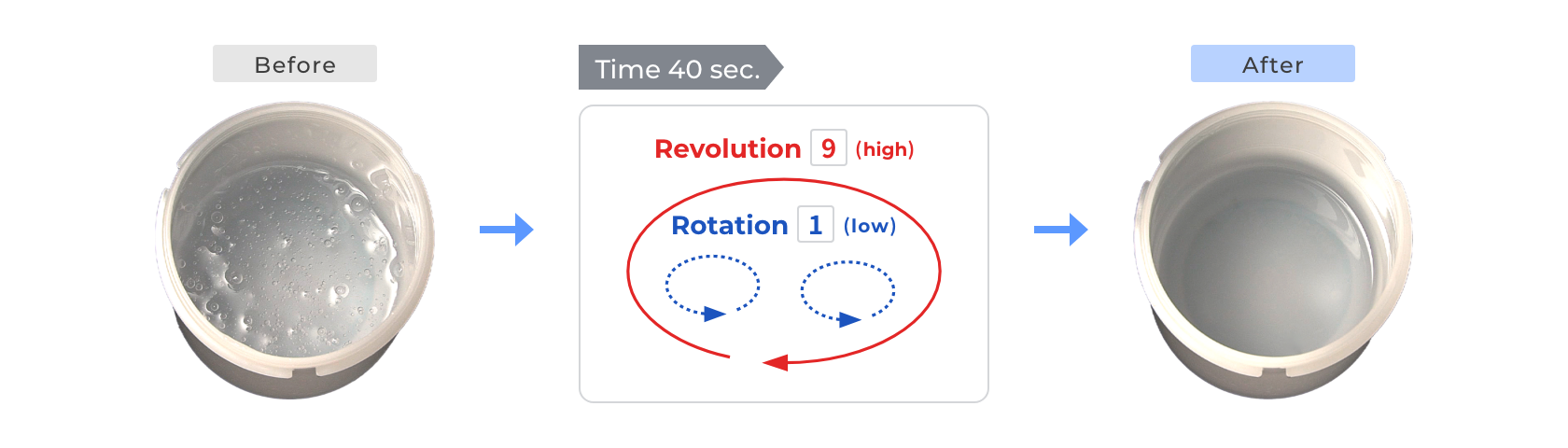

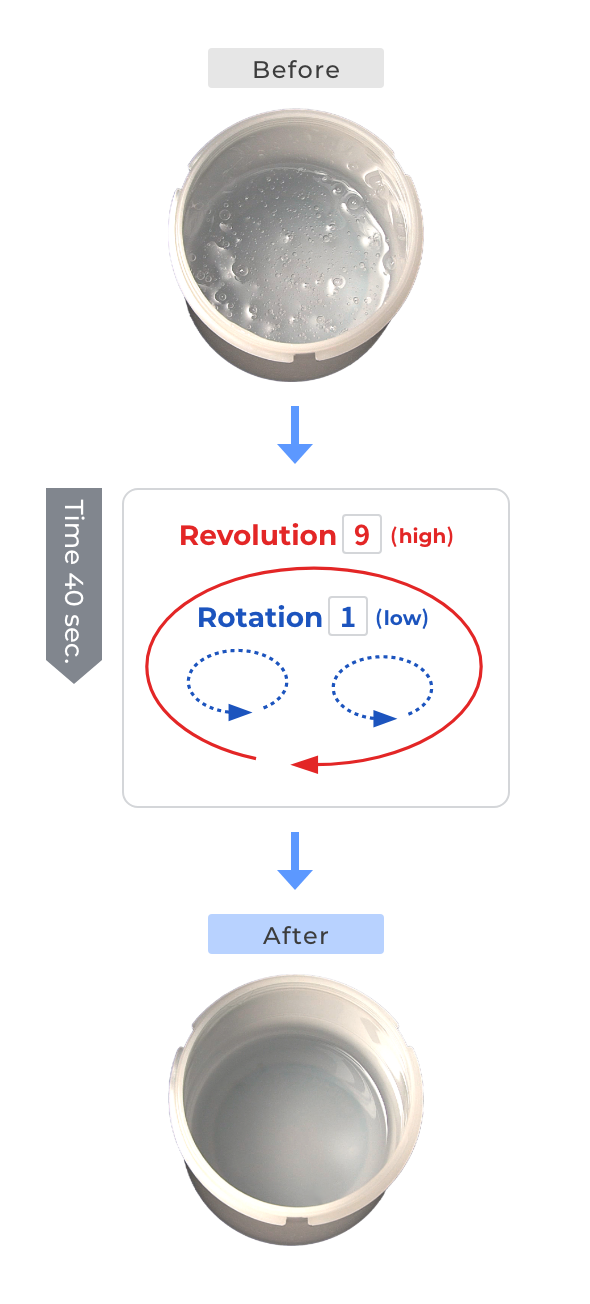

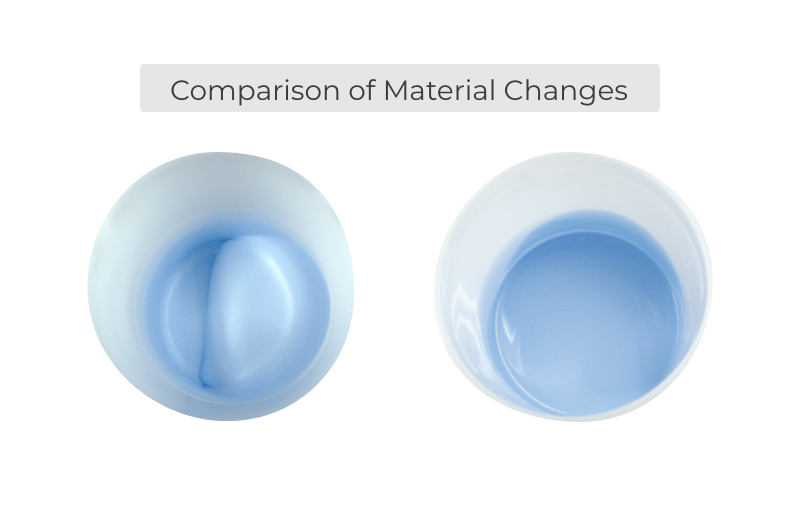

Defoaming is performed by the powerful centrifugal force of revolution in a short time.

Application example

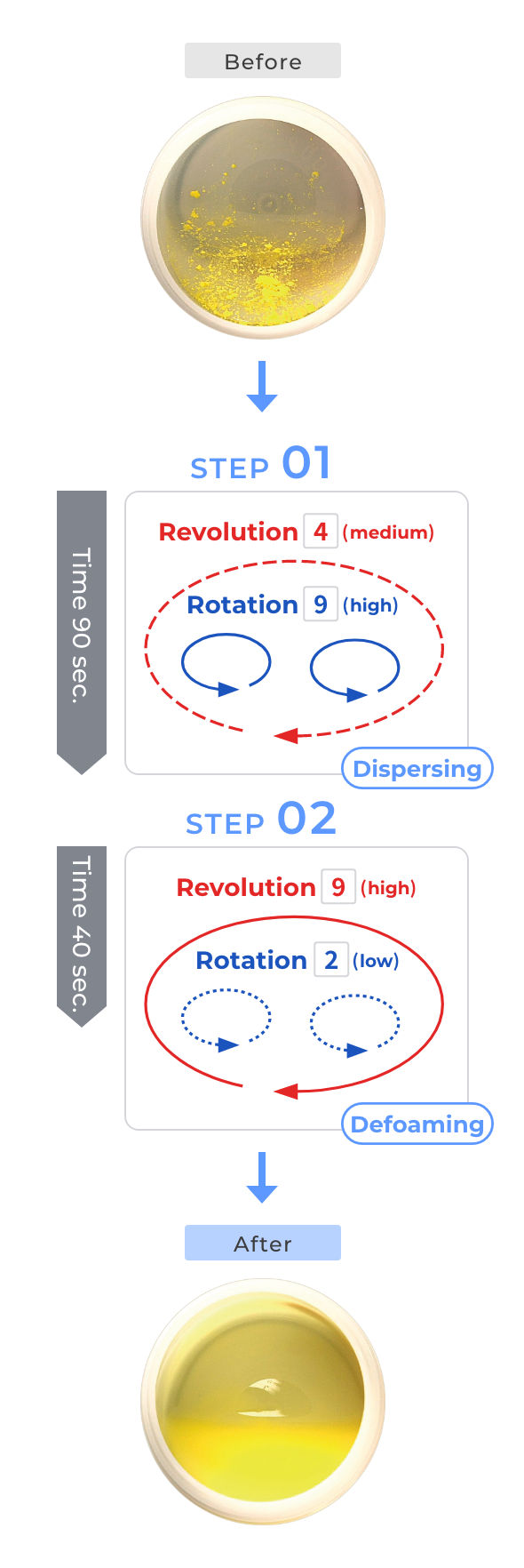

Defoaming of silicone resin (example of defoaming with the SK-350TII)

Temperature rises are suppressed

by the Individual Revolution and Rotation Speed Control system

For mixing high-viscosity materials, the speed of revolution needs to be increased, where the temperatures of materials rise sharply due to the friction with containers.

Care must be taken since some materials change with temperature rises, but the individual revolution and rotation speed setting function enables mixing and defoaming while suppressing such temperature rises.

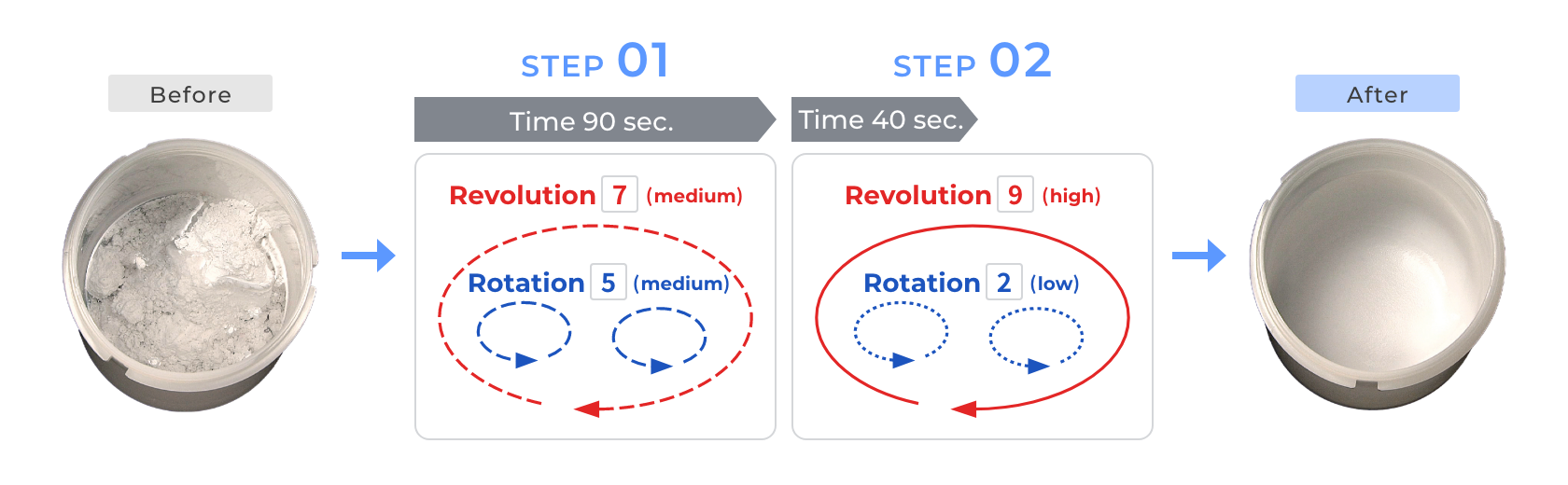

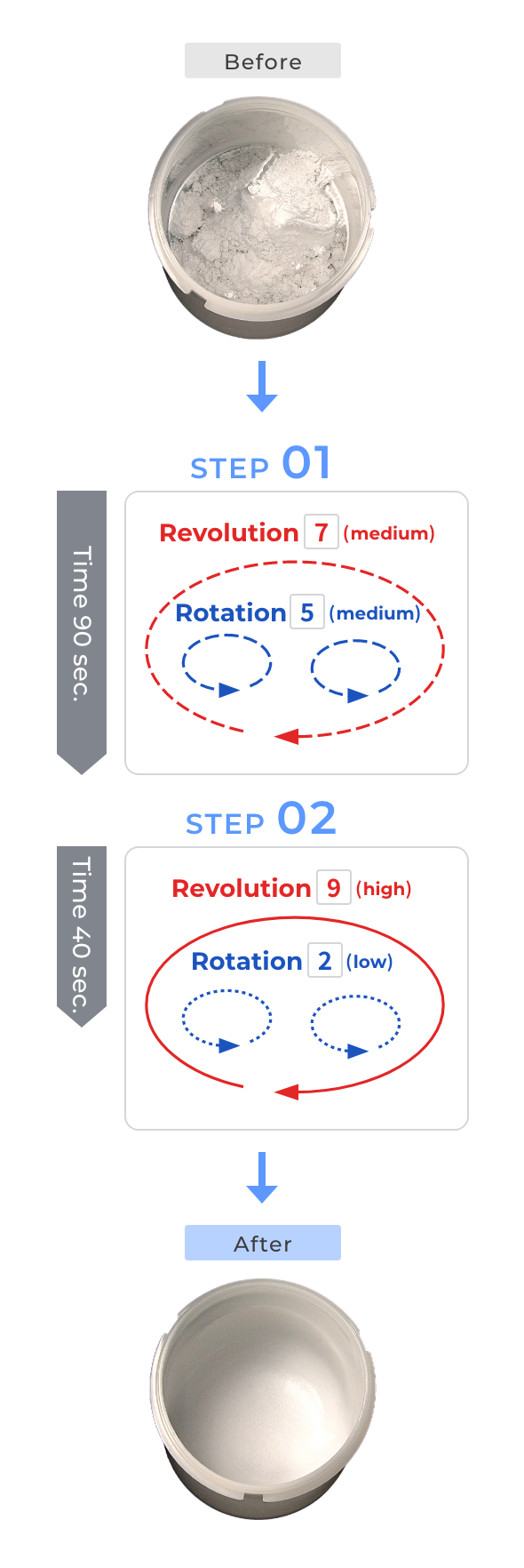

The mixing ability is enhanced and the issue of lumps is resolved by the Individual Revolution and Rotation Speed Control system and step operation.

In mixing powder and resin, the powder tends to form lumps, making it difficult to crush.

By using the individual revolution and rotation speed setting function and step operation, mixing and defoaming can be performed while preventing lumps.

Application example

Pasting of alumina and silicone resin (example of mixing with the SK-350TII)

The mixing ability is enhanced by the Individual Revolution and Rotation Speed Control system and step operation!

Additionally, even microfine bubbles are removed by the vacuum reduced pressure function.

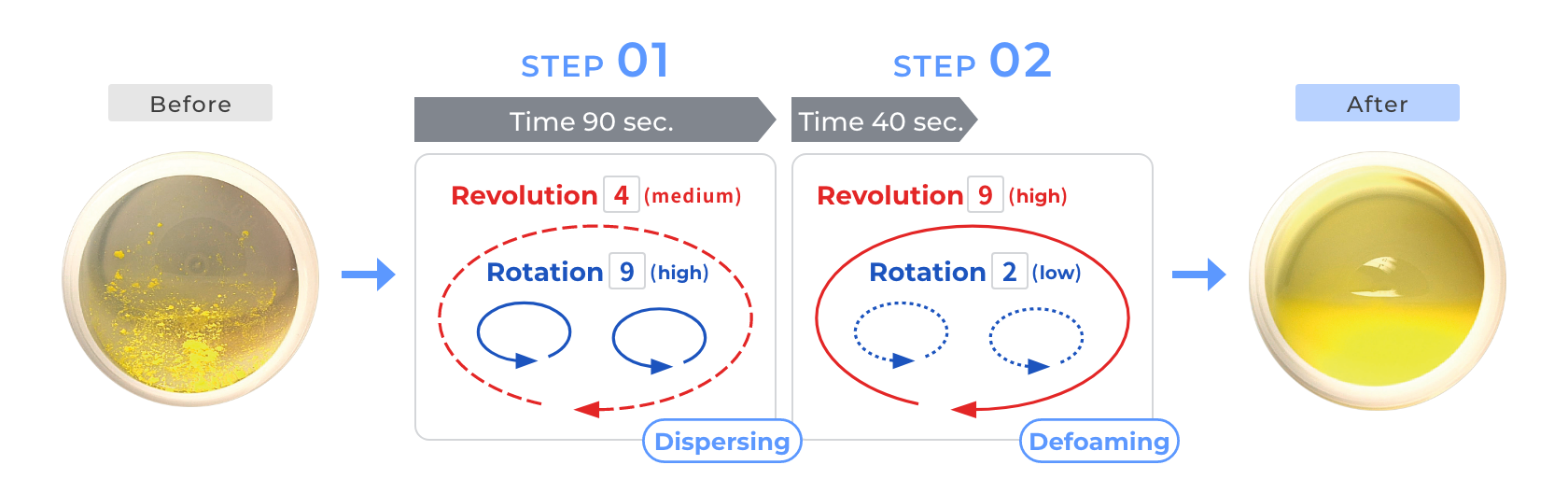

Defoaming can be performed after controlling precipitation by reducing the speed of revolution while keeping the speed of rotation required for mixing and dispersing by the individual revolution and rotation speed setting function and step mode.

Additionally, the defoaming effect is enhanced by vacuum reduced pressure.

Application example

Mixing and dispersing of fluorescent powder and silicone resin with different specific gravities(example of mixing with SK-300TVS-A)

For inquiries about our service and products, contact us from the link by clicking on the button below.

* You will be redirected to a page on another domain managed by us.

We have made available a brochure with detailed information about Kakuhunter and catalogs for each product model.

* You will be redirected to a page on another domain managed by us.

Developed and distributed by:

SHASHIN KAGAKU CO., LTD. Product Company

Weekdays 9:00 a.m. ~ 5:00 p.m. (closed on Saturdays, Sundays, and holidays)