Comparison with other methods

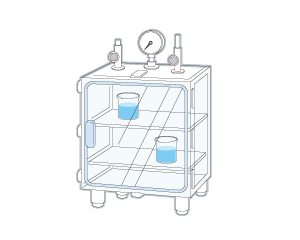

Vacuum degassing machine

[Advantages and disadvantages]

- Mixing is impossible.

- Due to the rise of the surface level of the liquid, the liquid may spill out.

- High viscosity materials take time to degas and it is difficult to degas the bottom part.

- Precise degassing take time and operation efficiency is poor.

- The material volatilization makes it degrease materials.

- Depending on the material, the composition may change.

Centrifuge

[Advantages and disadvantages]

- Mixing is impossible.

- Materials with different specific gravities occurs separation.

- In case of high viscosity materials, it may remain fine bubble.

- Material throughput is small.

Comparison with other degassing methods

| Method | Revolution and rotation method (Kakuhunter) |

Vacuum machine | Centrifuge |

|---|---|---|---|

| Degassing | ◎ Centrifugal degassing + vacuum | ○ Vacuum | ○ Centrifugal degassing |

| Degassing time | ◎ Short | △ Long | ◎ Short |

| Viscosity | ◎ Low to high viscosities | ◎ Low to medium viscosities | △ Low viscosities only |

| Generation of heat | △ Some generation of heat | ◎ No generation of heat | △ Some generation of heat |

| Compatible with syringes | ○ Usable from 3 cc to 360 cc (depending on the model) |

△ Level at which there is an effect | ○ Depends on the model |

| Work efficiency | ◎ Timer | × Visual observation required | ◎ Timer |