Comparison with other methods

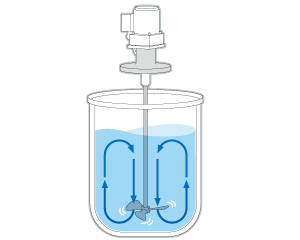

Propeller type

[Advantages and disadvantages]

- Mixing takes time.

- The propeller blades directly contact with the material, so loss of material occurs.

- The composition is sheered by the propeller blades, thus damaging the material.

- Accurate and uniform mixing is not possible.

- Cleaning job is required.

- Degassing is not possible.

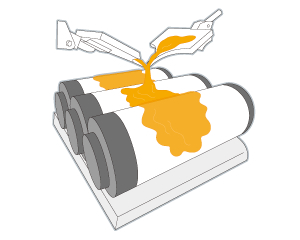

3-roll type

[Advantages and disadvantages]

- Mixing takes time.

- The rolls directly contact with the material, so loss of material occurs.

- Low viscosity material is not suitable.

- Cleaning job is required.

- There is a risk of caught in the rollers.

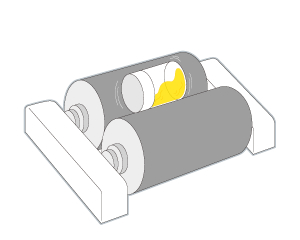

Roller type

[Advantages and disadvantages]

- Mixing takes time.

- Air bubbles could be generated during mixing or sedimentation and separation of materials after leaving some time.

- High viscosity material is not suitable.

Comparison with other mixing methods

| Method | Revolution-Rotation Type (Kakuhunter) |

Propeller Type | The Three Roll Type | Roller Type |

|---|---|---|---|---|

| Mixing Time | ◎ Short time | ○ Relatively short time | △ Long time | △ Long time |

| Material Viscosity | ◎ Low-High viscosity level | ○ Low-Middle viscosity level | ○ Middle-High viscosity level | ○ Low-Middle viscosity level |

| Degassing | ◎ Centrifugal degassing + Vacuuming | × Not possible | △ Can be effective | × Not possible |

| Foreign Substances Interfusion | ◎ Container | △ Propeller / Container | △ Roll | ◎ Container |

| Labor hour in case of replacing material | ◎ No need to clean up | × No need to clean up propeller and tank | × No need to roll part | ◎ No need to clean up |

| Heat Generation | △ Has heat | △ Has heat | △ Has heat | ○ Has less heat |

| Processing Quantity | △ Depending on container capacity | ◎ Possible to manage large quantity | △ Possible to manage continuous operation | ◎ Possible to manage large quantity |