Step operation (supported on all models)

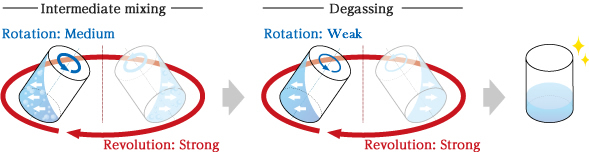

After mixing ⇒ Degassing (liquid + liquid)

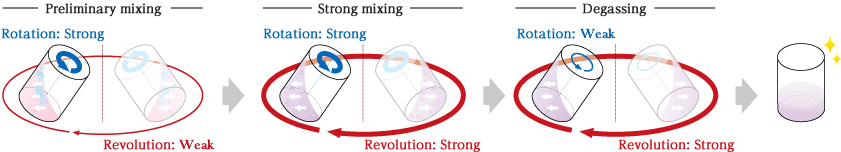

Dispersing (liquid+powder)

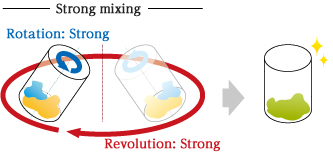

Mixing (kneading)

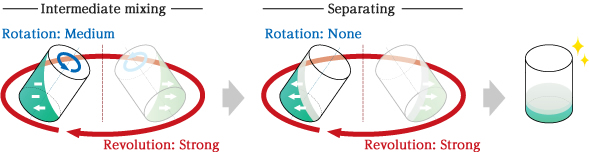

Mixing ⇒ Separating (materials with different specific gravities)

* The number of steps can be changed depends on the model.

Shifted cup tray

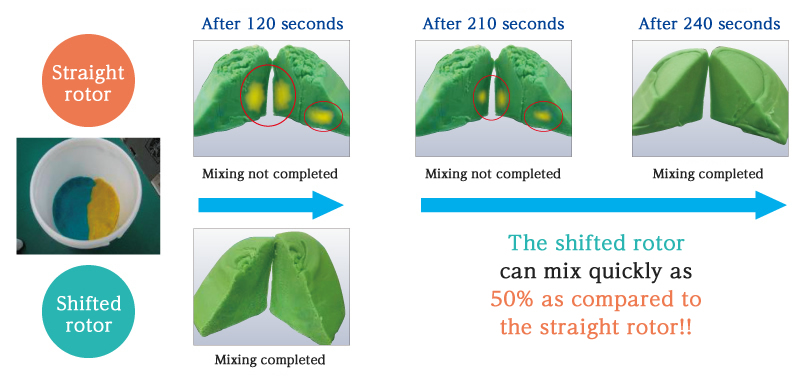

A shifted cup tray mounted used on the rotation axis to enhance mixing performance!

Shifting the cup tray increases the contact part between the container inner wall and material as compared to conventional cup tray (straight cup tray), improving the mixing performance.

Furthermore, long syringe can also be installed and by maintaining the distance from the central axis of revolution, centrifugal force is applied entirely to the material and it enables to mix effectively.

Comparison of mixing times (straight rotor vs. shifted rotor)

Compatible models

Vacuum reduced pressure function

The vacuum reduced pressure function makes it possible to eliminate even ultrafine air bubbles, so it can be expected to improve the conductivity and insulation performance demanded of electronic materials, to prevent reduced yield rate due to bubbles in optical material as well as to prevent injection of air due to air bubbles in syringes.

Also, the external vacuum pump enables a greater selection of vacuum pumps and easy maintenance.

The vacuum chamber is only shut off during vacuum reduced pressure operation, and only the rotor section is decompressed.

(SK-300SVII vacuum chamber)

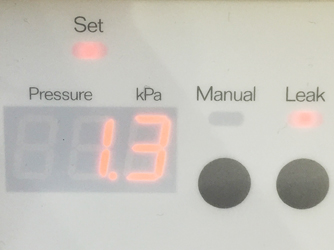

The degree of vacuum can be set voluntary (up to 1.3kPa) while monitoring the degree of vacuum pressure reduction.

* This machine can also be used as a vacuum chamber application without revolving.

Compatible models

Vacuum control system

On Delay

● Intentionally delaying the timing at which vacuum operation starts makes it possible to sustain thermal elevation and composition changes in the material.

● It restricts scattering of fine powder when mixing fine powder and liquid, prevents powder from sticking to the top lid of the container and avoids insufficient mixing and dispersion.

Off Delay

● Intentionally delaying the timing at which vacuum operation stops makes it possible to eliminate bubble generating while rotation totally stops and to enhance degassing accuracy.

SK-300TVS-A

SK-300TVS-A SK-350TVS

SK-350TVS SK-1100TVSII

SK-1100TVSII